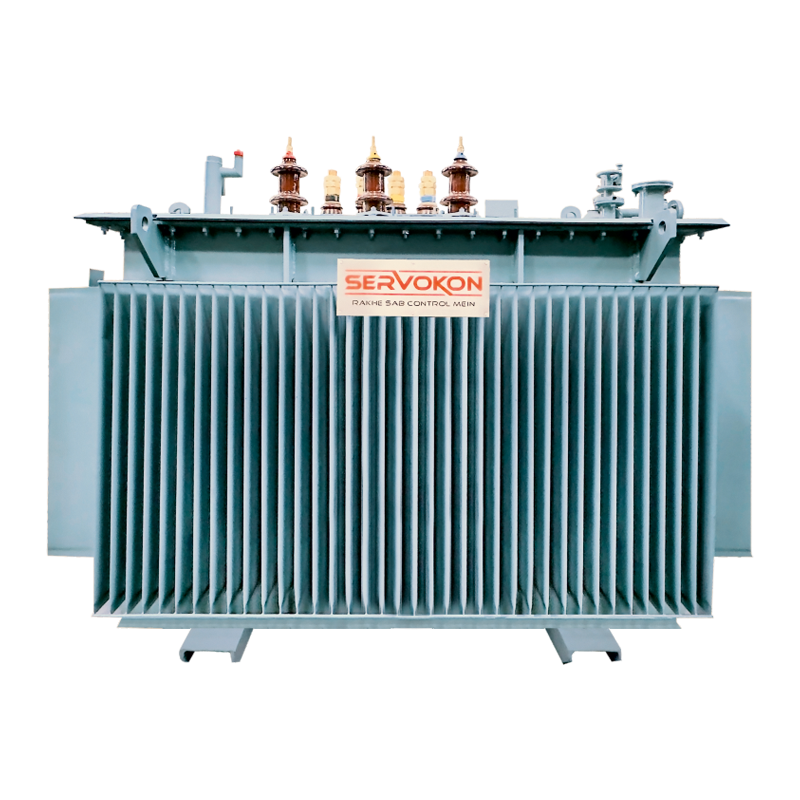

This technology is also known as Corrugated Transformer. The function and operations of these Transformers are similar like other conventional type Transformers but the construction of main tank is done with Corrugated Fins and MS Steels to provide the adequate cooling surface to avoid heating during operation. Corrugated Fins increase the surface area and take care of dissipation of heat, the Corrugated Fins once welded become integral part of Transformer's Tank structure. The skills and the workmanship of highly experienced and qualified welders ensure that the finished Tank is leakage free, the reliability of Tank's design is proven by over pressure test.

Hermetically Shield Transformers do not have Conservators and Silicagel Breather, the Dielectric Insulating Fluid / Oil is completely sealed in the Transformer Tank and therefore is not in contact to the atmosphere. The design avoids the entry of natural air in the Transformer Tank which prevent the sludging and oxidation in the Dielectric Fluid / Oil. Since the Insulated Oil does not come in contact with external air, there is hardly any deterioration of Oil over a period of time and hence such Transformers are virtually maintenance free.

Features

Limited Moisture in Oil

Longer Life of the Transformer

No Dehydrating Breather

No need to Oil Filtration

Limited Protection Devices Required

Compact Size

Best working in Polluted Area

Improve the reliability of the operation

Range We Offer

| Capacity | From 50 KVA to 5000 KVA. |

| Voltage Class | 1.1kV, 2.2kV, 3.3kV, 6.6kV, 6.9kV, 11kV, 12.47kV, 13.2kV, 13.8kV, 15kV 22kV, 25kV, 33kV, 34.5kV, 66kV, 69kV (Any Special Customised Class as per requirement) |

| Low Voltage Class | 380 V, 400 V, 415 V, 433 V, 440 V & 600 V, 690 V (Any Special Customised Class as per requirement) |

| Cooling | ONAN |

Reliable Power DistributionThese hermetically sealed transformers are engineered for industrial power distribution, ensuring safety, longevity, and consistent energy delivery under diverse operational conditions. Their CRGO core and customizable windings, paired with high energy efficiency, minimize losses and cater to a range of capacity requirements from 100 kVA up to 3150 kVA. Standardized to IS/IEC benchmarks, they ensure dependable operation with robust fire safety features available upon request.

Maintenance-Free and DurableWith a corrugated, hermetically sealed tank design, this transformer requires virtually no maintenance, cutting operational costs and maximizing uptime. The anti-corrosive, powder-coated finish and IP54 protection allow for both indoor and outdoor installations. Oil leakage and oxidation are prevented, prolonging the transformer's operational life even in high humidity environments.

Flexible Installation and CustomizationTransformers are designed for seamless installation in new or existing facilities, supporting customizable outputs and configurations. The optional on-load or off-circuit tap changers accommodate voltage requirements, and variants are available for different temperature ranges, coil structures, and winding materials to suit specific customer needs. Exported and supplied throughout India, they fit industrial setups for varied power ratings and operational demands.

FAQ's of Hermetically Sealed Transformer:

Q: How does the hermetically sealed design benefit transformer operation?

A: The hermetically sealed, corrugated tank prevents moisture and air ingress, ensuring the transformer oil remains uncontaminated. This helps prolong operational life, eliminates routine maintenance, and maintains optimal insulation properties, especially in high-humidity environments up to 95%.

Q: What is the purpose of using a CRGO core in these transformers?

A: CRGO (Cold Rolled Grain Oriented) steel is used for the transformer's core to ensure low core losses and high efficiency. This material supports a stable magnetic flow, resulting in better performance and reduced energy losses during operation.

Q: Where can these transformers be installed?

A: These transformers are suitable for both indoor and outdoor installations, thanks to their IP54 protection level, anti-corrosive finish, and robust construction. Their design allows them to function efficiently in diverse climates and industrial terrains.

Q: When should I choose On-load Tap Changer (OLTC) versus Off-circuit Tap Changer (OCTC)?

A: OLTC should be chosen when voltage adjustments are needed without interrupting operation, which is common in applications with fluctuating loads. OCTC is suitable where voltage changes are infrequent and can be made during maintenance shut-downs or periods of low demand.

Q: How is fire safety addressed in this transformer?

A: Fire retardant features are available upon request. The mineral oil used is specifically selected for its insulating and cooling properties, with transformer designs that comply with IS/IEC safety standards enhancing fire resistance.

Q: What process is followed to ensure transformer quality and standards compliance?

A: Each transformer is manufactured following IS 2026 and IEC 60076 standards, with rigorous testing for short-circuit withstand capacity, rated impedance, and load losses. This guarantees their performance, safety, and reliability for power distribution.

Q: What operational benefits do these transformers offer for industrial power users?

A: They provide high efficiency (up to 98%) with minimal losses, are maintenance-free due to the sealed tank, offer customizable output up to 3150 kVA and 36 kV, and operate quietly (less than 65 dB), ensuring both performance and an improved working environment.